Projects

Deeper technical summaries of selected projects, focusing on decisions made, engineering tradeoffs, and what was learned through iteration.

Real-Time Avian Radar Interface Concept (L’SPACE NPWEE)

This project explored a concept for a real-time avian radar interface to improve airspace awareness and safety. The work emphasized clear visualization, usability under time pressure, and practical integration with existing aviation workflows.

Engineering Focus

- System-level thinking: what information matters, when it matters, and how it should be presented

- Human-centered design: readability, cognitive load, and reducing ambiguity in alerts

- Integration mindset: working within constraints of existing tools and procedures

What I Contributed

- Supported proposal-style documentation and iteration based on feedback

- Helped refine requirements and how the interface should communicate risk and urgency

- Worked in a structured review environment with deadlines and formatting constraints

Color-Tracking Turret System

A mechatronics build designed to detect and track targets based on color, then fire once a reliable lock is achieved. The main challenge was turning noisy sensing into stable behavior and controllable motion.

Technical Approach

- Sensing + logic: detect target color and define “lock” criteria to avoid false triggers

- Actuation: position control to track target location smoothly

- System behavior: tune responsiveness vs stability (avoid oscillation and overshoot)

Key Design Decisions

- Chose simple, reliable lock conditions before firing (robustness > sensitivity)

- Separated detection from actuation control to keep tuning manageable

- Focused on repeatable behavior rather than “one perfect run”

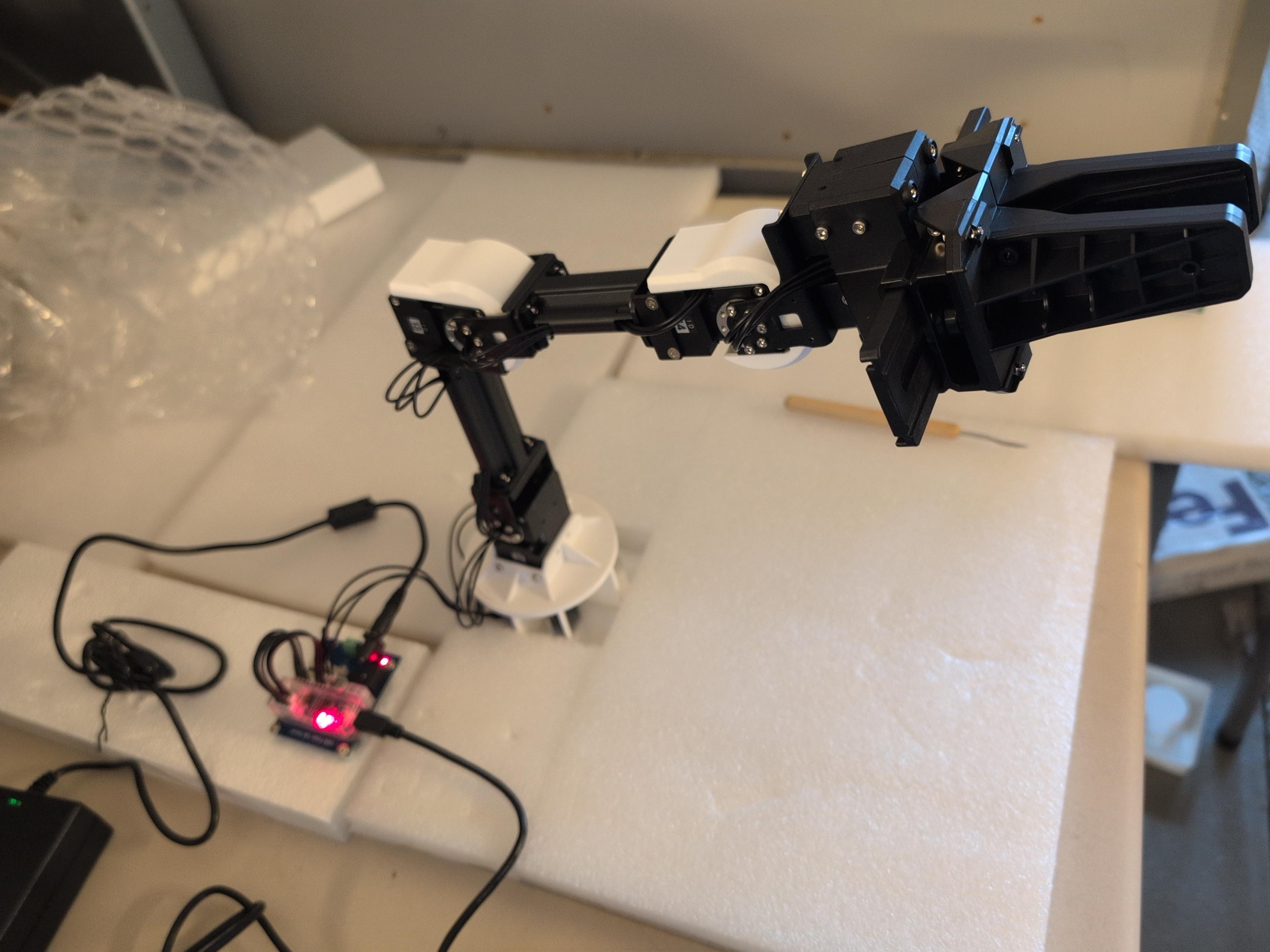

Bandage Peeling Robot & Adhesion

A research-driven concept focused on adhesion and peel mechanics for a bandage-peeling robot. The goal is to better understand how peel force changes with geometry, speed, and material behavior, and then use that understanding to control motion profiles that reduce discomfort.

Technical Focus

- Peel mechanics: connecting model intuition to what a robot can actually control (speed, angle, force)

- Modeling ideas: exploring frameworks such as JKR and cohesive-zone concepts

- Design mindset: creating a concept that can produce useful data, not just a one-off demo

Next Steps

- Define measurable experiments and what “good peel” looks like (low peak force, smooth force profile)

- Develop repeatable test procedures and identify the most sensitive variables

- Iterate hardware and control based on results

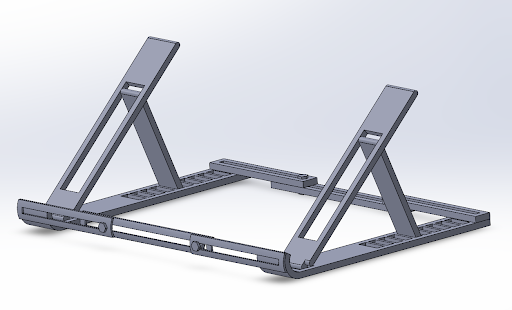

Adjustable Laptop Stand: Structural Analysis

A mechanical design project centered on creating a stable, adjustable laptop stand that safely supports a heavy load at multiple angles. The work emphasized mechanical reasoning: load paths, stability, and practical sizing checks.

Analysis & Checks

- Stability: overturning moments and worst-case loading angles

- Strength: stress checks and sizing for critical components (pins/joints)

- Failure modes: Von Mises stress, buckling considerations, and fatigue awareness

Design Outcome

- Selected geometry and joint sizing based on conservative loads

- Focused on robustness across multiple configurations, not just one “best” position

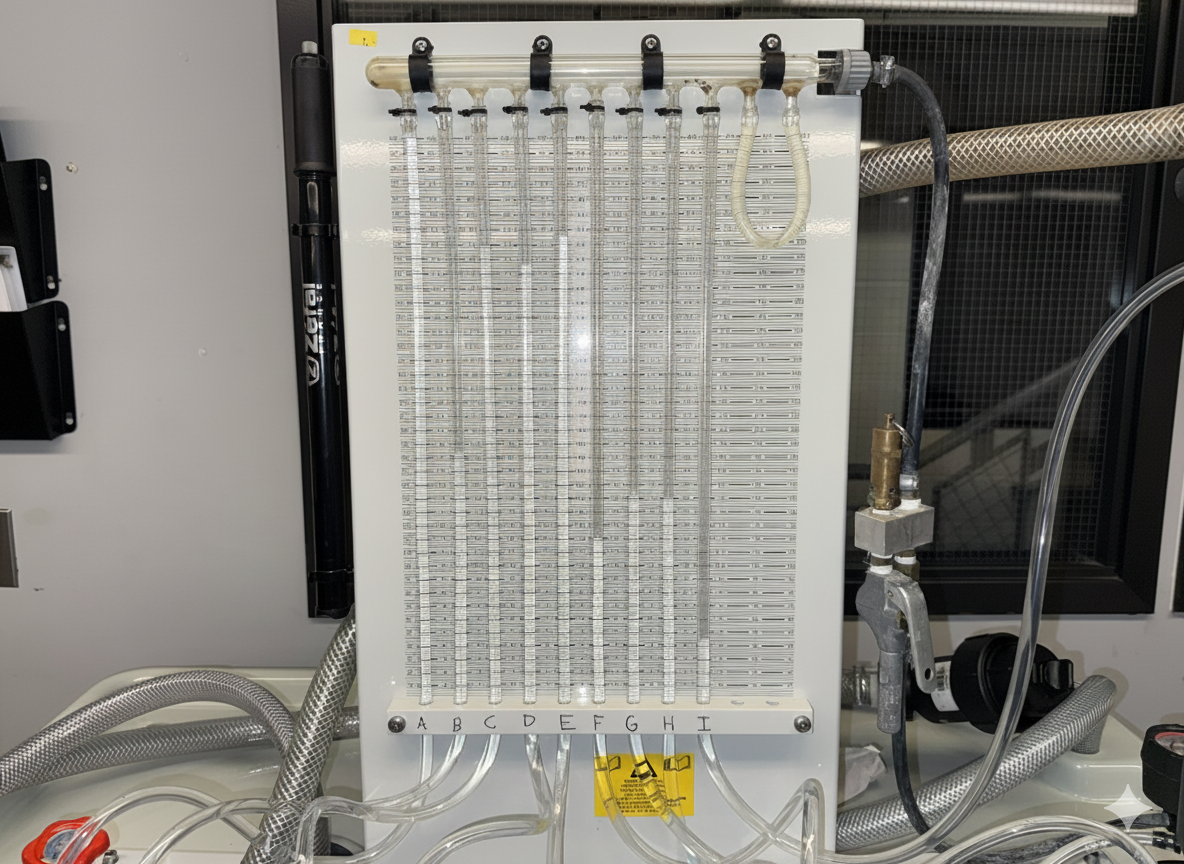

Instrumentation & Experimental Methods (Rutgers Labs)

Completed multiple measurement labs involving strain, pressure/flow, and data acquisition. The emphasis was on calibration, uncertainty, and using real data to support engineering conclusions.

Core Skills Practiced

- Calibration and curve fitting with attention to error sources

- Uncertainty analysis and propagation

- DAQ workflows and experimental procedure discipline